This is one of the old customers we have been working with for nearly three years.

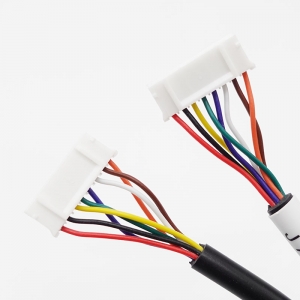

Since March 8, 2017, they have sent us a new cable assembly called a touch plate cable. All components are black in color. Just like the drawing of the finished assembly. (This is the cable supplied by the original manufacturer)

The cable begins with a coiled extension with a 3.5 mm jack plug (10 feet length when uncoiled) and the banana plug is soldered to the sleeve of the jack. It requires a 16" 24 AWG black wire soldered to the tip and ring pins of the phono jack. The solder joint is covered by several layers of thermal shrinkage of the banana plug.

16" the other end of the wire is soldered to a small Neodymiun magnet and then pressed into a black plastic bucket.

But we have a new idea to make the magnet over-molded.

From the two molds we offered for the barrel, our customer had chosen the one where the magnet stick out and will be higher.

Then we found the possibility of demagnetization when the magnet was soldered or molded. So we introduced the heat resistant magnet. We also listened to his suggestion that the magnets were allowed to stick to the steel which acted as a heat sink during the welding process.

In January 2018, we sent samples to them for confirmation. It seems that they are satisfied with the sample.

In July of the same year, they began to order, 4 times orders in total, 500 pieces each time.

We are constantly improving the details during the production process.

For example, we made the wires crimped a bare copper terminal in case the wire is too thin to be damaged when the banana plug is screwed on.