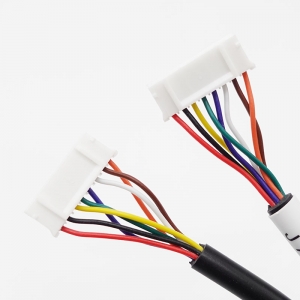

Step 1: Design and Preparation of Wire Harness

Based on the requirements of customers, the layout of electronic devices, and functional demands, the engineering team will formulate a detailed design scheme for the wire harness.

This encompasses determining the length, structure, terminal type, wire specifications, and connection mode of the wire harness, among others. During the design process, multiple factors such as maintainability, waterproof performance, and anti-interference ability of the wire harness need to be taken into consideration. Once the design is accomplished, engineers will employ CAD software for drafting and generate corresponding technological documents.

The processing steps of the wire harness are as follows:

1. Material Preparation

The materials necessary for wire harness processing include wires, insulating sleeves, connectors, etc. Materials of the appropriate specifications and models are selected in accordance with the design requirements.

2. Wire Stripping

Wire stripping refers to removing a section of the external insulation layer of the wire to facilitate connection with terminal connectors or sockets. This step requires the operation of wire strippers and cutting knives to ensure that the wire is stripped cleanly and neatly.

3. Wire Crimping

Different colored wires are combined as per the design requirements and connected using crimping tools. During the crimping process, workers need to pair the wires correctly in accordance with the markings on the design drawing.

4. Insulation Sheathing

Insulation sheathing is implemented to enhance the safety and stability of the wire harness. Workers cut the insulating sleeves to the required length and fix them onto the wires using heat shrink sleeves or glue to protect the wires from the external environment.

5. Finished Product Testing

Upon the completion of wire harness processing, a finished product test is conducted. The test mainly comprises conductivity testing, insulation testing, and anti-nterference testing, etc. Through these tests, it can be ensured that the quality and performance of the wire harness conform to the standards.

6. Packaging and Delivery

The warehouse manager undertakes the packaging, and a logistics company is arranged for transportation. During the transportation process, measures such as shock resistance and waterproofing need to be taken to ensure the integrity of the wire harness.

How are wiring harnesses processed?

2024-10-31

-

JST Patch Loom Wire Harness

ISO9001:2015 Qaulity control manufacturing Machinery Cable Assembly

-

12v BNA Loom Adaptor Wire Harness

ISO9001:2015 Qaulity control manufacturing Machinery Cable Assembly

-

For Food Bakery Machines with Large Wiring Harnesses

ISO9001:2015 Qaulity control manufacturing Machinery Cable Assembly

-

OEM ODM OBD2 to DB9 Cable Automobile Diagnosis Connection Cable

- Auto Troubleshooter Connection Cable

SEND A MESSAGE

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

online service

-

86-0592-6088856

-

+86 181 0695 3755